Weigh Pads

Rugged, Reliable And Accurate Weighing Solutions

Play Video

Essae Steel WB

Overview

Weigh pads play a pivotal role in rapidly and accurately computing loads carried by various vehicles like lorries, vans, and HGVs.

These pads are particularly beneficial as they enable the assessment of individual axle weights and verify that the overall gross weight of the vehicle does not exceed the prescribed maximum limit. This capability ensures compliance with regulations and enhances road safety by preventing potentially hazardous overloading situations.

Very lightweight at 19 kg each, these pads can be placed on any compacted, level surface for weighing purposes. Due to their low weight, a single person can easily carry the weigh pads. Truck axle weights can be measured by positioning each axle on the weigh pads. The weigh pads have a height of only 20 mm, making it effortless for any vehicle to drive onto them. This feature makes the weigh pads particularly useful for mobile enforcement and checking truck axle weights.

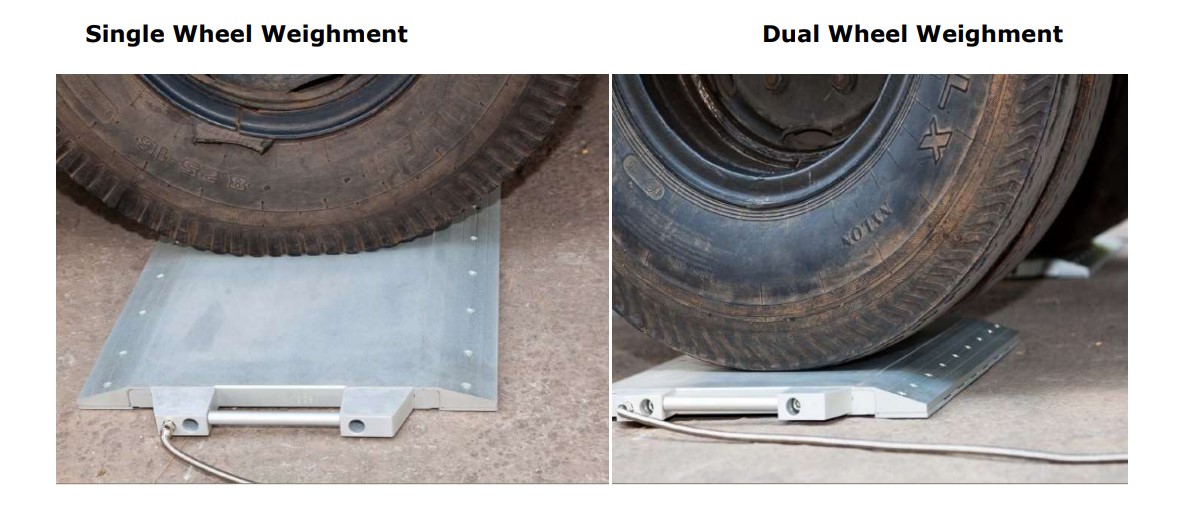

Each weigh pad has a capacity of 20 tons, with dimensions of L-700 mm x W-365 mm x H-27 mm. When two pads are used together, they can weigh axle loads of up to 40 tons. These pads are interconnected to a weight indicator. With a height of 27mm, vehicles of any size can easily drive onto the pads.

Portable weigh pads find common use in weighing trucks on the road. Their lightweight design allows one person to carry them with ease, and they can be placed on any compacted ground or road surface for truck weighing. (For optimal accuracy, it is recommended to use the weigh pads on a level road.) To measure the axle weight of trucks, two pads should be placed on the road.

Features

Enabling manufacturers to win

Lightweight, easy to transport and handle, suitable for convenient transportation.

Built with flat plate design, delivers precise response with high frequency and accuracy.

Utilizes aerospace-grade material, excelling in anti-overload capability and strength.

Implementing unique treatment, provides IP66 protection, and suits various environmental conditions.

Specifications of Weigh Pads

| Output sensitivity (mV/V) | 0.9 ±0.2 |

| Combined error (%ld) | 0.5 |

| Non-linearity (%ld) | 0.5 |

| Repeatability (%ld) | 0.1 |

| Input resistance ( Ω) | 3120 ±40 |

| Output resistance (Ω) | 2800±10 |

| Insulation resistance (MΩ ) | ≥5000(100VDC) |

| Zero balance (%FS) | 4~10%FS |

| Temperature effect on sensitivity (%FS/10̊C ) | 0.1 |

| Temperature effect on zero (%FS/10̊C) | 0.1 |

| Temperature, compensated ( ̊C ) | -10~ +50 |

| Temperature, operating( ̊C ) | -40~ +80 |

| Excitation, recommended (V) | 9~ 15DC |

| Excitation, max.(V) | 20DC |

| Safe overload (%FS) | 120 |

| Ultimate overload (%FS) | 150 |

| Protection class | IP66 |

| Cable Spec. | 4-wire shield cable |

| Max. load for single point (t) | 20t |

| Rated capacity (t) | 20t |

Explore projects Details