Keeping your Weighbridge Healthy

Weighbridges are very useful tools for weighing vehicles but its performance depends on proper maintenance. Here is a guide to keeping your weighbridge healthy and in good working condition.

Regular Inspection

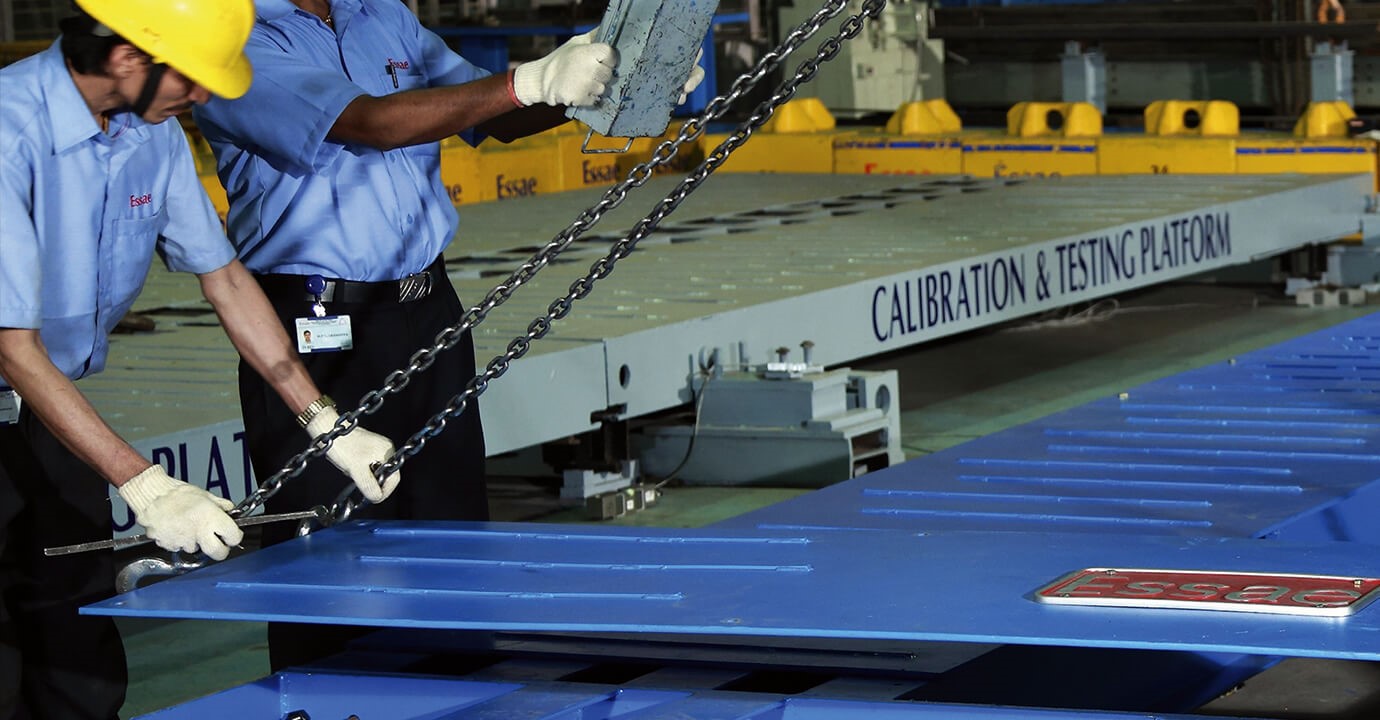

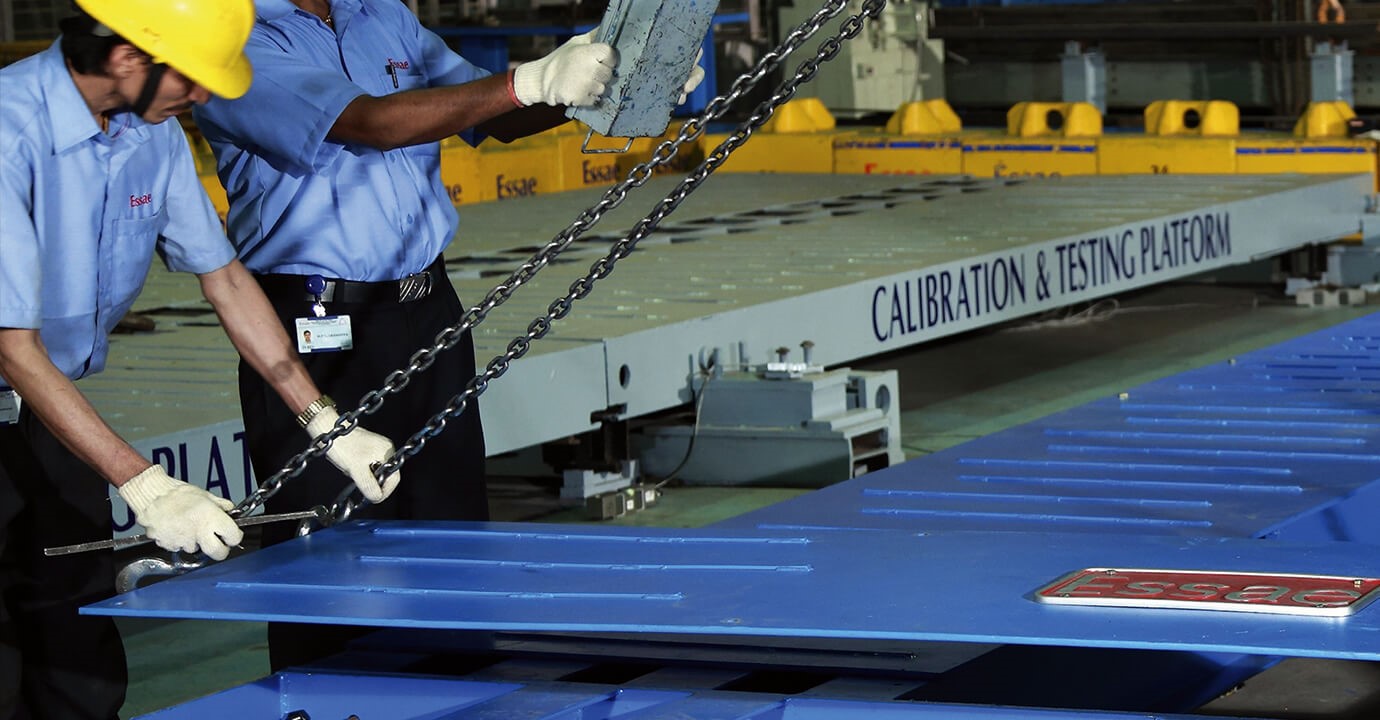

There are two types of weighbridges-pit mounted and surface mounted weighbridges. In the case of pit mounted weighbridges, daily inspection is required to clean the mud and dirt buildup that may affect the performance. In the surface mounted weighbridges, ensure that there is sufficient space between the weighbridge superstructure itself and the ground below.

Periodic weekly and monthly maintenance schedules have to be maintained for both types of weighbridges. Conducting weekly tests can help you identify problem areas and do maintenance. The vehicle has to be kept at one end of the weighbridge, middle and towards the end and measurements recorded. If there is a huge difference between the data generated, it may require expert help to correct the problem. This test can be done on a monthly basis too.

In the surface mounted weighbridges, ensure that there is no build up of debris that may obstruct the load cells. Removal of the debris has to be done without causing damage to the connection cables.

Monthly cleaning using a jet washer will help in removal of dirt but ensure that water does not seep into the junction box or damage the load cells.

Overloading and Heavy Braking

Overloading can cause damage to the load cells, the mounting hardware, the deck and its foundations. Drivers have to be trained to avoid high speed on the weighbridge. It can cause jerk loading on the load cells. There should be speed restriction signs put up to caution drivers against over speeding.

Power Supply

Weighbridges should be connected to a stable and good quality power sources. Proper earthing is a must for prevention of high voltage causing damage to load cells. Welding on the weighbridge can cause damage to the load cells, electrical and electronics systems. Seek professional advice in such matter.

Blocked Drainage, Cable Problems

In places where there are water logging problems, the sealing of the load cells may be affected by fatigue or corrosion. Ensure that extra water is drained away. Cables can be damaged by rats and hence rodent-proof cables must be used to prevent damage to circuits and load cells.

Predictive Maintenance

Instead of dealing with a problem after it has occurred, predictive maintenance using cloud technology ensures that weighbridges are assessed in real time and performance logs created. This can be accessed by engineers for preventive maintenance. The system will also alert on load-cell or instrument malfunction. This technology is suited for single and multi-site operations.

Periodic maintenance and proper care of the weighbridge is a must for error-free operations and long life of the machine. Weighbridge companies can give guidance properly in this regard. Essae Digitronics can provide guidance in maintenance of weighbridges.